.png)

Optimised catalysts for PEM Fuel Cells & Water Electrolysers

PGM based Electrocatalysts and Inks

Our new range of catalysts for PEM technology, HyPer, is the culmination of a cross company development program using our teams of scientists in the US & UK. This has achieved a range of products which offer improved durability and give higher electrochemical performance aiding the further adoption of this vital technology in the fight against climate change.

Proton Exchange Membrane (PEM) technology relies on catalysts, namely platinum, iridium & alloys containing PGM's. It is the use of heterogeneous platinum group metal catalysts that allows PEM technology to give superior flexibility (such as rapid start up) and high levels of performance at ambient temperatures.

PGM's are rare metals and trade at high prices. To mitigate this, the metals are used in finely dispersed form to maximize the surface to volume ratio. Today, the best catalysts consist of 2-8 nm particles displaying a very large specific surface area.

In fuel cells, to prevent the sintering of these small nanoparticles, which can cause a decrease in catalytic activity during operation, the metal is often deposited on high surface area supports to prevent particle-particle contact. This also reduces the amount platinum required optimizing the use of the metal and limiting the impact on price.

The HyPer range uses an improved metal deposition technique, specialist selection of carbon support materials and post production treatments to achieve their improved durability and higher electrochemical surface area.

HyPer FC - Fuel Cell catalysts

HyPer WE - Water Electrolyser catalysts

Fuel Cell Products

Description

ECSA (g Pt)

HyPer FC 100

HyPer FC 120

HyPer FC 140

HyPer FC 150

HyPer FC 150X

HyPer FC 170X

HyPer FC 200

High Surface Area Platinum Black

20% Platinum on a conductive carbon support

40% Platinum on a conductive carbon support

50% Platinum on a conductive carbon support

50% Platinum on a high surface area carbon support

70% Platinum on a high surface area carbon support

50:50 atomic ratio Platinum Ruthenium

15m2/g

80m2/g

55m2/g

50m2/g

>100m2/g

70m2/g

70m2/g

TEM image = HyPer FC 140

HyPer FC grades offer higher levels of durability and greater retention of electrochemical performance

HyPer FC grades show improved electrochemical performance and higher ECSA

TEM image = HyPer FC 150X

Electrolyser Products

Description

BET Surface Area

HyPer WE 100

HyPer WE 150

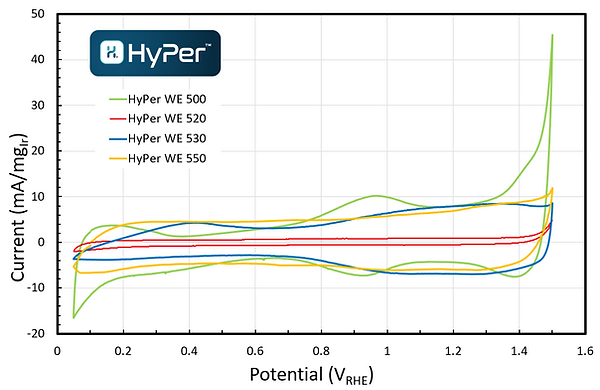

HyPer WE 500

HyPer WE 520

HyPer WE 530

HyPer WE 550

HyPer WE supported

High Surface Area Platinum Black

50% Platinum on a conductive carbon support

Iridium Black

Iridium Oxide

High Surface Area Iridium Oxide

Iridium Ruthenium Oxide

Contact us to discuss supported iridium anode catalysts

25 - 40m2/g

>100m2/g

20-40m2/g

45 - 60m2/g

120 - 150m2/g

120 - 150 m2/g

-

HyPer WE 550 - Iridium Ruthenium Oxide

HyPer WE 550 - Iridium Ruthenium Oxide has a long track record of use in the field (>10 years) and offers demonstrable improvements in durability under the harsh conditions of the electrolyser anode.

Ames Goldsmith Ceimig’s unique production process results in a truly intimate alloy of iridium & ruthenium, meaning ruthenium is stable in the catalyst layer and offers synergistic benefits in terms of performance.

Contact our team to discuss ink or paste manufacturing for your fuel cell or water electrolyser application

If you have a Fuel Cell application or require specific material characteristics which are unavailable from current products Ceimig offers a Custom Compound Synthesis Service (CCSS) to help you meet the more challenging requirements.